Due to the explosion in online shopping, inefficiency in the supply chain has become a serious problem. Everyone wants their items delivered yesterday, and to make that happen, logistics needs to be smarter and faster. That’s why the Logistics industry is turning to Artificial Intelligence (AI). In fact, by 2027, the artificial intelligence market within the logistics and supply chain sector is expected to attain a valuation of $10.07 billion.

In this blog, we will understand the pros and cons of Logistics AI and understand the application of Artificial Intelligence in logistics in various Logistics operations. Let’s begin.

How AI is Reshaping Logistics?

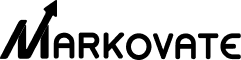

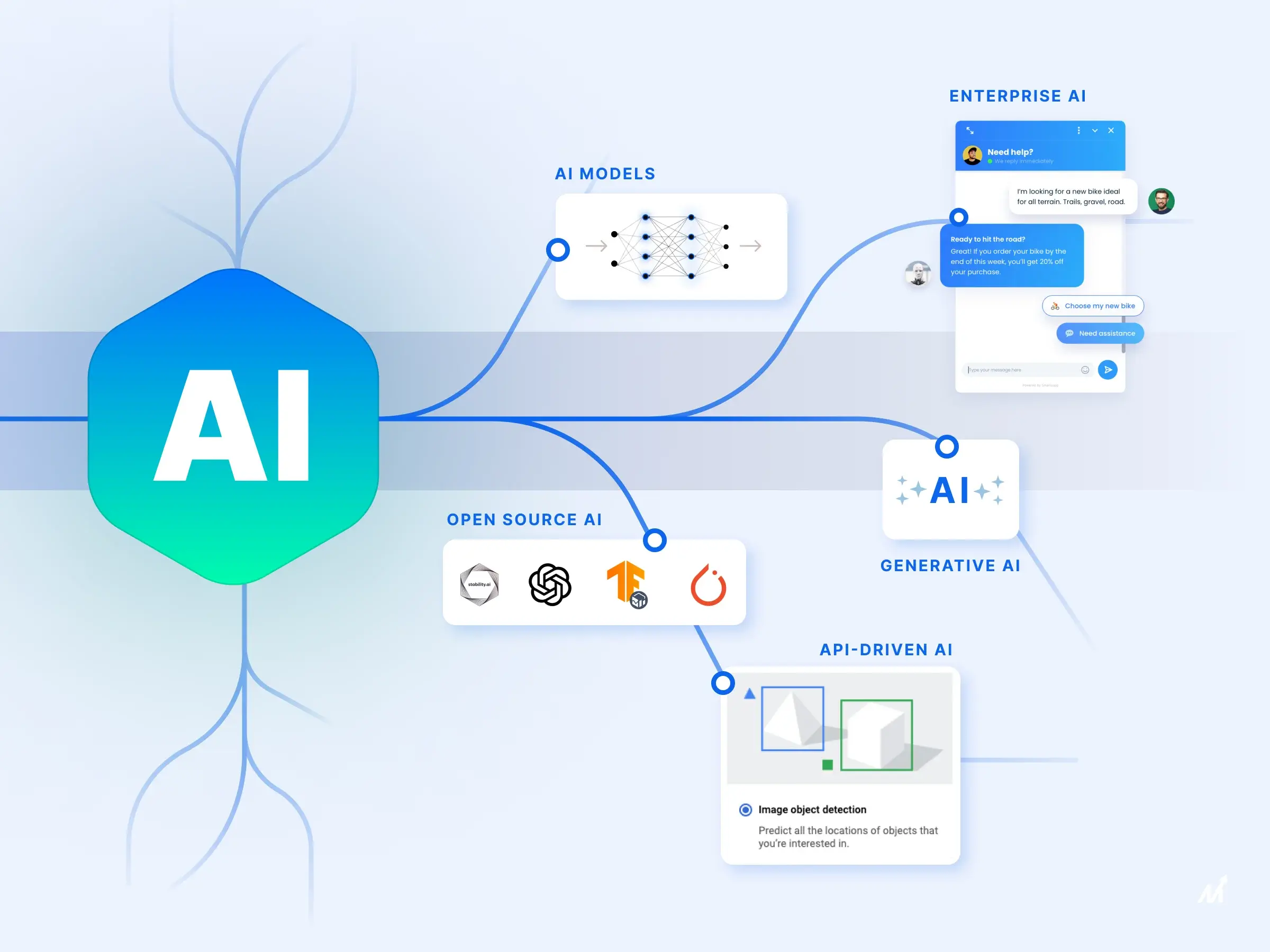

In the hectic world of moving products from factories to consumers, there are loads of hurdles that companies have to clear. It’s not just about making a product; it’s about getting it to the buyer in the most efficient way possible. That’s where Artificial Intelligence, or AI, comes into play. Here are areas where AI is helping Logistics a lot:

1. Stuck with Outdated Info?

In the old way of doing things, you might not know a shipment was delayed until it was already too late. Now, with AI, you get real-time alerts about hiccups in your operations, so you can handle them on the fly.

2. Unsure About Your Data?

When you’re running a business, guessing games can cost you. AI doesn’t guess; it uses rock-solid algorithms to make sure the data you’re using to make decisions is as accurate as it can be.

3. Inventory Headaches?

Nothing worse than having a warehouse full of stuff nobody wants while running out of hot items. AI takes the guesswork out of inventory, using smart predictions to ensure you have what you need when needed.

4. Shipping Costs Through the Roof?

Freight costs can be a killer. AI plays detective to find you the cheapest, most efficient routes, potentially saving you a ton of cash in the long run.

5. Resource Management Woes?

Whether it’s figuring out how many trucks you need on the road or how much stock to keep in the warehouse, AI’s got your back. It gives you the insights you need to keep things humming along smoothly.

6. Feeling Held Back by Outdated Systems?

If you’re stuck in the past, you’re losing out. AI is constantly evolving, learning from trends to help automate the boring stuff and keep your business on the cutting edge.

7. Tired of Late Deliveries?

Your customers don’t like waiting, and neither do you. AI tracking systems can keep an eye on all your shipments, making sure everything gets where it’s going when it’s supposed to.

8. Worried About Theft or Fraud?

Unfortunately, theft and fraud are realities in any business. AI can quickly flag suspicious activities, letting you take action before a small issue becomes a big problem.

9. Bogged Down by Inefficiencies?

Streamlining your operations is key to staying competitive. Whether it’s automating simple tasks or integrating self-driving vehicles, AI helps you do things faster and better.

10. Struggling with a Lack of Transparency?

In any supply chain, stuff happens. With AI, you can keep tabs on that stuff every step of the way, from the factory floor to the customer’s door, making it easier to fix issues quickly.

11. Customer Service Slacking?

People have questions at all hours. AI chatbots can handle those queries anytime, day or night, keeping your customers happy and taking a load off your support team.

12. Trouble Spotting Bottlenecks?

Even with top-of-the-line systems, it’s tough to spot problem areas in real time. AI dashboards give you a live look at your operations, so you can clear bottlenecks before they clog up the works.

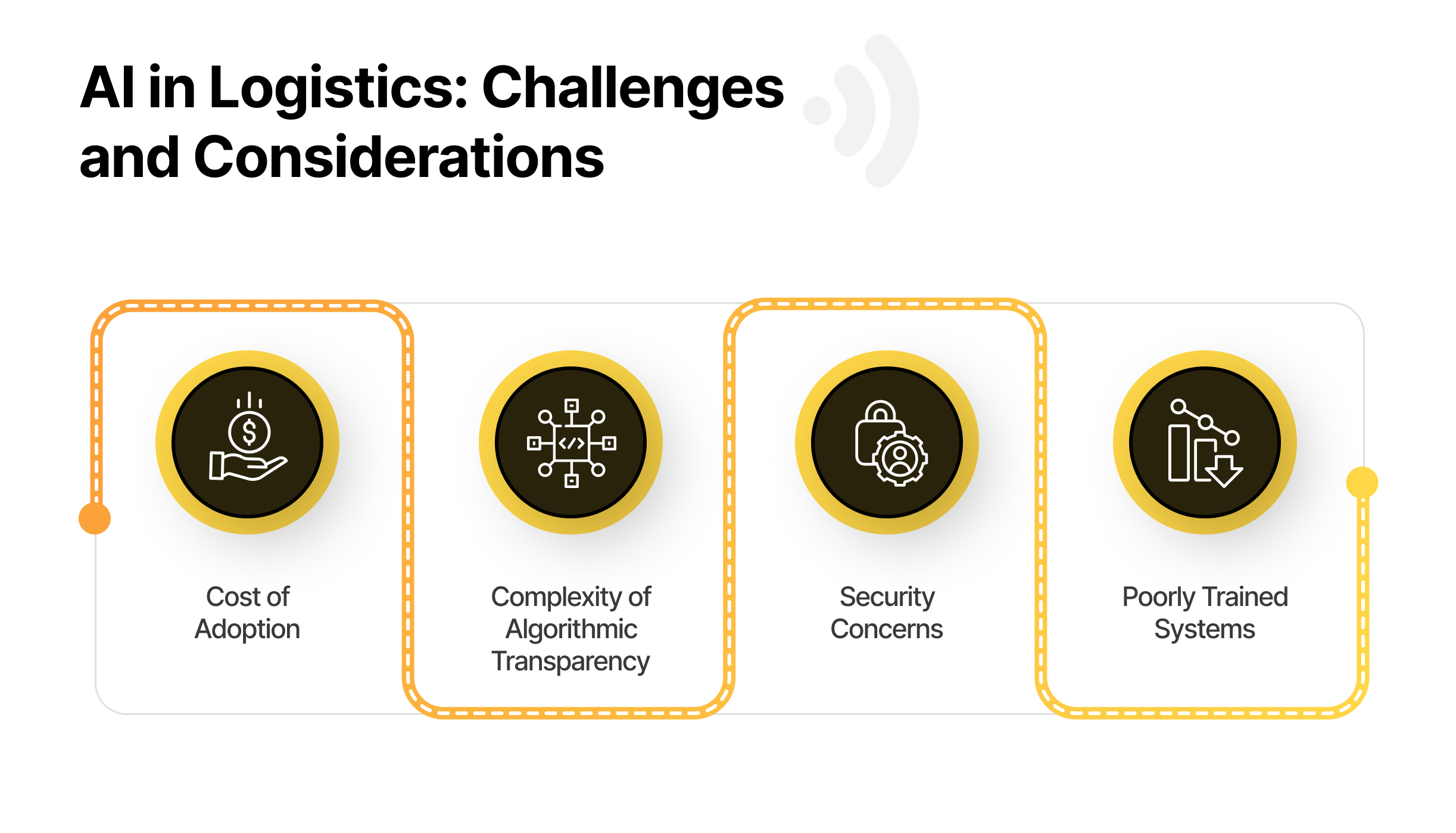

AI in Logistics: Challenges and Considerations

1. Cost of Adoption

While AI has the potential to yield significant cost savings for logistics companies, the initial transition does entail a comparatively high upfront investment. This encompasses hardware, software, and the specialized personnel needed to manage these systems effectively. As such, companies must critically evaluate whether the long-term benefits justify the immediate expenditure.

2. Complexity of Algorithmic Transparency

While Logistics AI excels in automating decision-making processes, this strength can also introduce a significant challenge: the algorithms can be so intricate that they become nearly incomprehensible. Such opacity can be a roadblock when employees or even experts try to understand the rationale behind machine-driven decisions. This lack of transparency becomes even more critical when the technology is deployed in business-critical applications.

3. Security Concerns

Whenever data is involved, security is a concern. In the logistics industry, the use of AI amplifies the critical need for robust data security to protect both operational integrity and customer trust. Failure to secure data not only risks operational disruptions but also exposes the business to regulatory penalties and loss of customer confidence.

4. Poorly Trained Systems

Finally, bad data means bad decisions. When an AI system is trained on suboptimal data—whether it be flawed, limited in scope, or originating from an insufficiently diverse sample size—the repercussions are far-reaching. A model developed on such data becomes inherently limited, and its decision-making process is compromised. It can manifest in various forms, including algorithmic biases or skewed interpretations that could lead to poor, if not damaging, decisions. Such outcomes not only diminish the credibility and usefulness of the AI system but also have broader implications. They could affect policy-making, business strategies, and even human lives. Therefore, it is crucial that any dataset used to train an AI model be comprehensive, diverse, and of high quality to mitigate the risk of developing a system that perpetuates errors or biases.

So, should your logistics or supply chain business invest in AI technology? It’s not a simple yes or no answer. AI offers tremendous upside but comes with its own set of challenges that must be managed. A thoughtful approach, maybe in consultation with AI experts, is the best course of action for businesses considering making the leap.

23 Use Cases and Application of AI in Logistics Operations

Explore the transformative power of AI in logistics, from optimizing supply chains to enhancing route planning. Dive into real-world use cases where AI algorithms are streamlining operations, reducing costs, and giving businesses a strategic edge. Learn how AI’s capabilities are reshaping the logistics landscape for the better

1. Algorithmic Process Scrutiny

Algorithmic Process Scrutiny employs machine learning technologies to systematically dissect and scrutinize logistical and operational data within the supply chain ecosystem. This sophisticated technique not only amplifies the understanding of intrinsically complex supply chain frameworks but also facilitates the streamlining of said frameworks by discerning inefficiencies and points of failure. Algorithmic Process Scrutiny goes beyond mere monitoring—it deploys machine learning to foresee market fluctuations and proactively adapt logistical parameters.

2. Supply Chain Refinement Mechanics

Utilizing machine learning algorithms, Supply Chain Refinement Mechanics scrutinize copious volumes of data to architect a proactive, performance-enhancing framework. The AI technology gauges vital supply chain metrics and pinpoints vulnerabilities or prospects for enhancements while simultaneously measuring parameters such as customer satisfaction indices, fulfilment ratios, and inventory fluidity.

3. Automated Vendor Interface Systems

Automated Vendor Interface Systems apply machine learning to overhaul the dynamics of interactions with third-party service entities. By dissecting colossal data repositories, these systems glean nuanced customer behaviour profiles and accordingly advise on value-generating services. Additionally, Automated Vendor Interface Systems formulate dynamic strategies for governing supplier relationships while abating risks associated with supply chain processes.

4. Logistical Process Automatization

Leveraging machine learning algorithms, Logistical Process Automatization irons out redundancies and automates procedural tasks within the supply chain. From consignment labelling to orchestrating timetables for dispatch, these algorithms not only automate but also employ predictive analytics to preemptively adapt to customer needs, thereby streamlining the entire order fulfilment architecture.

5. Self-Navigating Freight Solutions

The proliferation of self-navigating, AI-integrated freight vehicles indicates a seismic shift in how goods traverse within a supply chain. By amalgamating advanced machine learning algorithms, these freight solutions significantly diminish the requirement for human intervention, thereby enhancing both cost-efficiency and operational efficacy. Autonomous vehicles redefine how supply chains perceive resource allocation, leading to a more streamlined and fiscally responsible operational model.

6. Prescriptive Maintenance Modules

Prescriptive Maintenance Modules employ machine learning to perpetually monitor the performance metrics of supply chain and logistical equipment. The AI-driven analytics of these modules pre-empt equipment malfunction by alerting administrators to latent hardware incongruities before they escalate into full-blown operational debacles. Such modules thus significantly pare down unscheduled maintenance costs.

7. Adaptive Demand Conjecture Systems

By harnessing the capabilities of machine learning, Adaptive Demand Conjecture Systems scrutinize market trends and customer behaviour, thereby generating exceedingly accurate demand projections. These advanced AI integration solutions also assist in devising meticulous inventory management blueprints, thereby averting scenarios that involve either stockpiling or a deficit of critical inventory.

8. Cognitive Warehouse Governance

Cognitive Warehouse Governance employs machine learning algorithms to enhance the efficacy of inventory storage and auditing procedures. Beyond mere automation, these systems fine-tune receiving, compilation, and dispatch processes, ultimately leading to substantial resource conservation and financial prudence.

9. Dynamic Route Formulation Algorithms

Dynamic Route Formulation Algorithms wield machine learning to analyze intricate customer data and subsequently determine the most resource-efficient delivery pathways. These algorithms substantially contract delivery timelines and amplify customer satisfaction indices by creating optimized logistical routes.

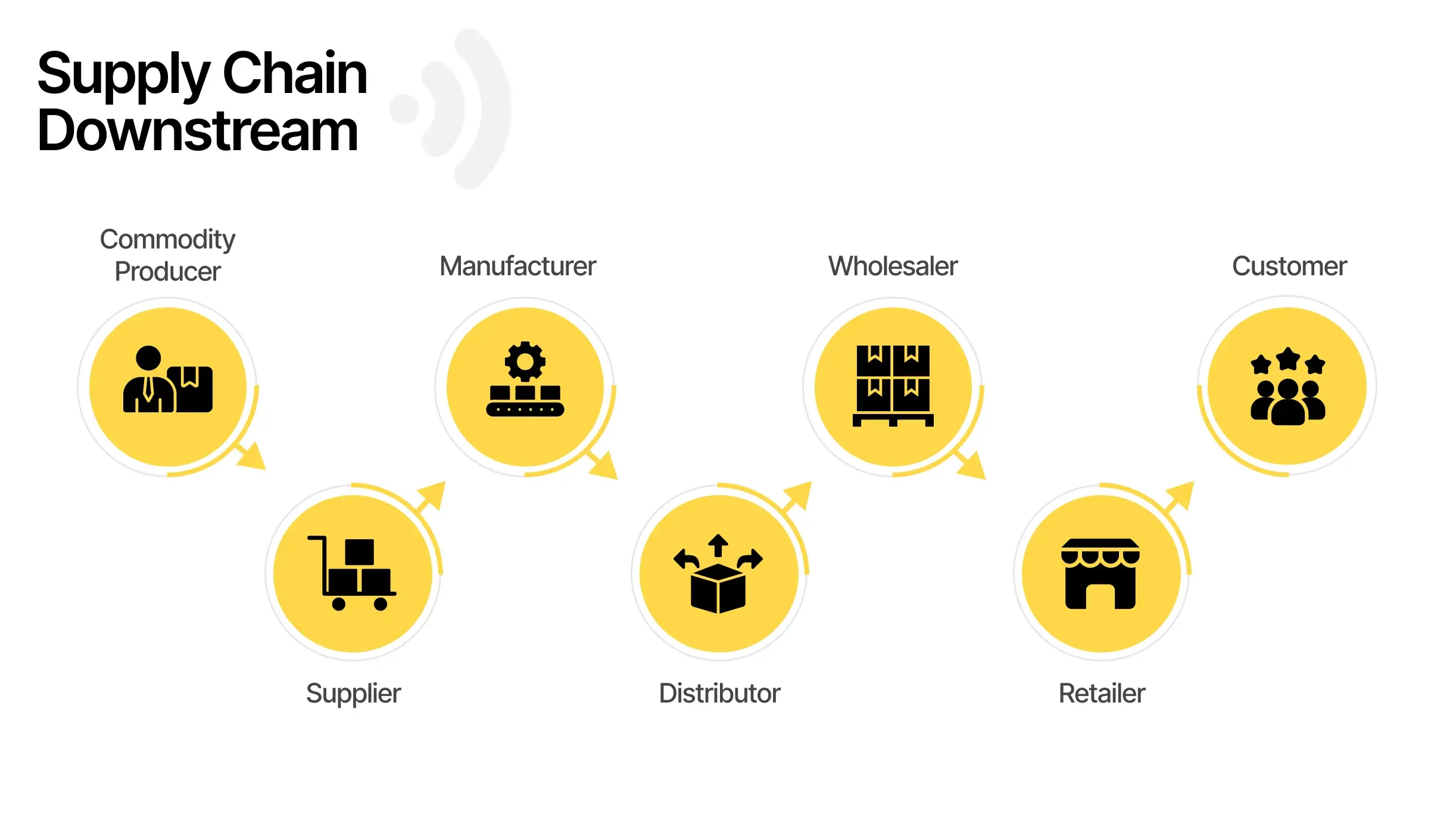

10. Tailored Last-Mile Dispatch Solutions

Tailored Last-Mile Dispatch Solution is key in logistics operations. These solutions employ machine learning algorithms to hyper-personalize the terminal phases of product delivery. From bespoke same-day delivery options to crafting custom delivery trajectories based on intricate customer data, these algorithms drastically curtail both time and fiscal resources expended during last-mile logistics.

11. Inventory Optimization Strategies

Artificial Intelligence (AI) plays a vital role in fine-tuning inventory levels by anticipating market demands. Through the power of predictive analytics, it equips businesses to enhance both profit margins and supply chain efficiency by proactively managing supplies. Advanced machine learning models sift through historical data, seasonality patterns, and market trends to offer actionable insights for strategic inventory control.

12. Product Quality Assurance Automation

Harnessing AI’s computational prowess allows for the automation of stringent quality checks during the manufacturing process. Machine learning algorithms paired with computer vision techniques actively monitor production lines, flagging any irregularities or defects. This ensures a consistent delivery of high-quality products while significantly reducing human error and operational costs.

13. Risk Profiling for Supplier Interactions

Incorporating Logistics AI into the supply chain also elevates risk management to a new plane. Using predictive analytics and machine learning models, AI platforms scrutinize supplier interactions, payment history, and reliability metrics to develop comprehensive risk profiles. These data-driven insights enable businesses to anticipate and mitigate supply chain disruptions effectively.

14. Intelligent Freight Coordination

The transport sector has also seen transformative changes with AI’s introduction. Algorithms now possess the capability to match freight requirements with suitable carriers, optimizing logistical efficiency while driving down operational costs. The technology can further streamline booking procedures, enhance cargo tracking, and significantly improve client satisfaction metrics by reducing shipment delays.

15. Seamless Document Digitalization

Operational efficiency is significantly enhanced through AI-powered document processing solutions. These platforms rapidly scan, interpret, and digitally archive essential paperwork, making data retrieval exponentially faster. Advanced OCR (Optical Character Recognition) technology ensures the accuracy of the digital conversion, thereby eliminating the need for time-consuming manual data input.

16. Warehouse Energy Consumption Regulation

AI technologies also venture into the realm of energy optimization within supply chain facilities. Utilizing IoT sensors and machine learning algorithms, these systems continually assess and adjust energy utilization in real-time. This not only reduces energy expenditure but also contributes to a more sustainable operational model.

(Read about AI in Sustainable Development – Energy & Environment)

17. Intelligent Order Fulfilment Systems

AI platforms redefine the paradigm of order management by automating the entire workflow. Advanced algorithms consider a myriad of factors, such as optimal routing, stock availability, and delivery timelines, to improve operational efficiency. Moreover, machine learning models analyze customer interaction history to tailor services, thereby enhancing customer satisfaction.

18. Real-Time Shipment Oversight

Transparency is a critical factor in modern supply chain management, and Logistics AI brings this into sharp focus. AI-driven platforms provide real-time updates on shipment status, flagging any potential delays or disruptions. This facilitates proactive problem-solving, enabling customers to adjust their expectations and plan accordingly.

19. Self-Navigating Transportation Units and Aerial Freight Carriers

The advent of self-guided vehicular technology, commonly referred to as autonomous vehicles, is fundamentally altering the last-mile delivery mechanisms. Such vehicles drastically minimize the dependency on the human workforce for deliveries, thereby leading to both efficiency and cost advantages. In a parallel vein, aerial freight carriers, colloquially known as drones, provide solutions for short-range consignments. These drones mitigate expenses ordinarily associated with traditional freight systems by accelerating point-to-point delivery.

20. Automated Operations through Intelligent Algorithms

Cognitive machine functions or Robotic Process Automation (RPA) significantly contribute to the optimization of tedious logistical activities, like information transcription, object labelling, and merchandise packaging. The implementation of robotic automation in these domains not only negates human errors but also amplifies operational accuracy. The outcome is a net reduction in time expenditure and financial costs.

21. Prognostic Computational Models for Supply Networks

The utility of Artificial Intelligence extends to devising forward-looking computational paradigms to forecast impending consumer needs. These AI-driven algorithms are proficient at scrutinizing consumer behaviour metrics for any indications of disruptions or anomalies. The final analysis yields strategic insights that serve as invaluable intelligence for preempting any glitches in the supply infrastructure.

22. Fabricated Data Environments for AI Refinement

The concept of synthetic data generation implies the structured creation of artificial data sets that serve as controlled environments for AI systems. These data reservoirs allow AI functionalities to iterate their decision-making algorithms, thereby affording them the opportunity to learn from previous inaccuracies. This perpetual learning loop essentially enhances the AI’s performance metrics and decision-making accuracy over successive iterations.

23. Anomaly Scanning for Fiscal Malfeasance Mitigation

In the space of logistics and supply chain management, Artificial Intelligence algorithms are increasingly being deployed for the identification and mitigation of financial irregularities. The Logistics AI undertakes an in-depth analysis of client transactional data to flag aberrant or suspicious behaviours. Doing so significantly reduces the company’s susceptibility to fraudulent activities and thereby fortifies customer trust and brand integrity.

By incorporating these machine learning-based technologies, enterprises can potentially revolutionize their supply chain and logistics frameworks. These are not mere incremental upgrades; they are transformative changes that could redefine operational paradigms for businesses and enterprises.

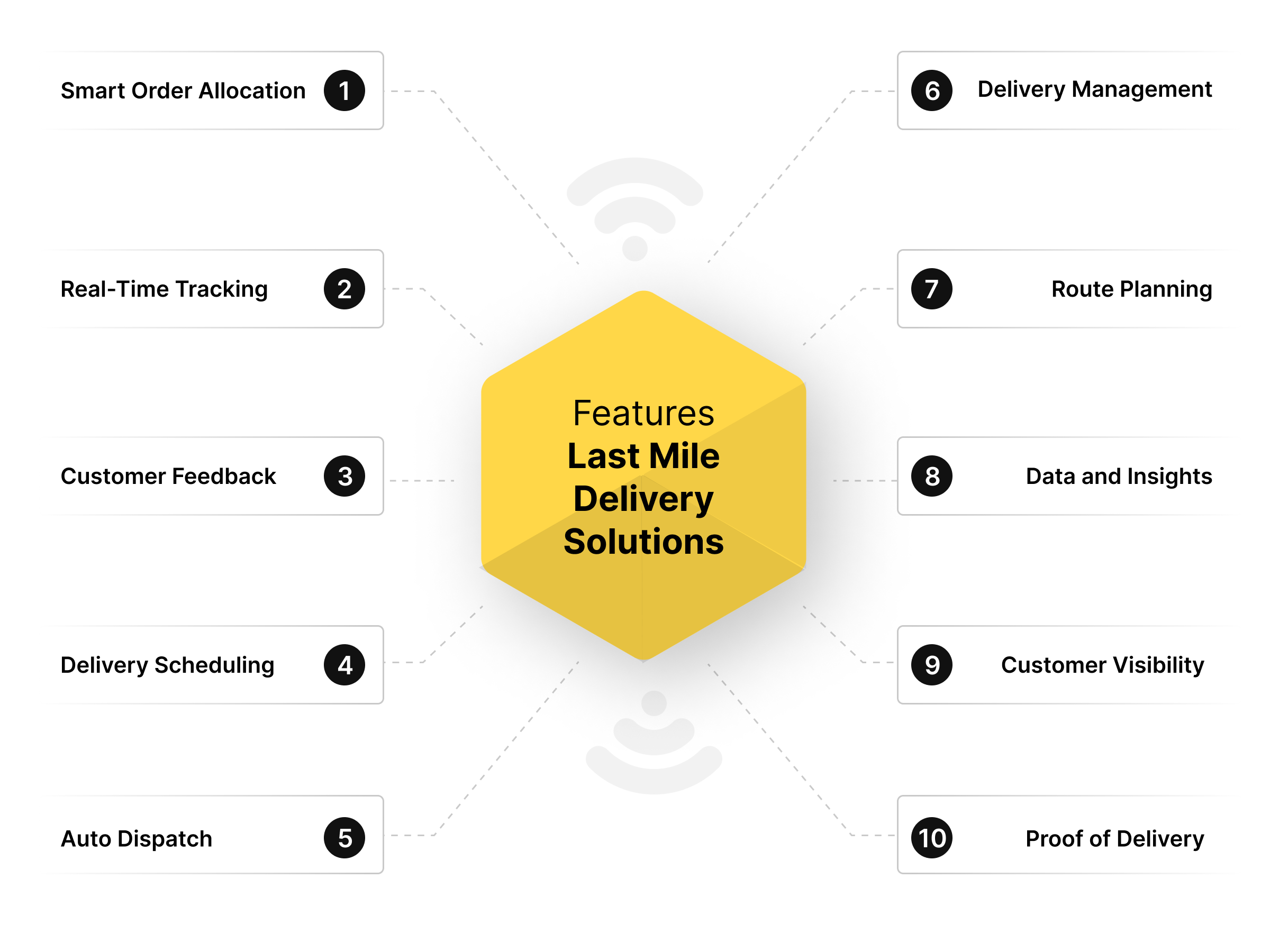

Loved this blog? Read about LLM use cases and applications too.

Leverage AI in Logistics with Markovate

Markovate is your go-to partner for bespoke AI solutions in the logistics sector. We’re not an off-the-shelf AI company; we tailor-make solutions based on your specific challenges and needs.

Are you grappling with inefficient shipping routes? We can develop algorithms designed to optimize your transportation network. These aren’t generic fixes; they are data-driven solutions uniquely calibrated to your operation, leveraging machine learning for continuous improvement.

Need better supply chain visibility? Our custom AI tools can assist in demand forecasting, dynamically adjusting to market trends and reducing holding costs. This means your inventory is where it needs to be when it needs to be there.

What sets us apart is our AI consulting approach. We don’t just build AI; we build AI that fits seamlessly into your logistics operations, aligning closely with your business objectives. This means not just operational efficiency but a strategic edge over your competitors.

Ready to revolutionize your logistics? Contact Markovate today for AI solutions that make sense for your business.

I’m Rajeev Sharma, Co-Founder and CEO of Markovate, an innovative digital product development firm with a focus on AI and Machine Learning. With over a decade in the field, I’ve led key projects for major players like AT&T and IBM, specializing in mobile app development, UX design, and end-to-end product creation. Armed with a Bachelor’s Degree in Computer Science and Scrum Alliance certifications, I continue to drive technological excellence in today’s fast-paced digital landscape.